From The Blog

News & Articles

- Heavenly Hoop Houses

- Dec 09, 2025

Best Materials for Pre Built Hoop Houses for Home Garden in Prescott

Prescott sits at 5,000 feet elevation in north-central Arizona, where the climate demands careful consideration when it comes to selecting greenhouse materials. The area experiences four distinct seasons, with winter lows around 10 to 15 degrees Fahrenheit, summer highs reaching the upper 80s, and an average growing season of roughly 176 days.

When investing in pre built hoop houses for home garden in Prescott, understanding which materials withstand these conditions determines whether your structure lasts a few seasons or several decades.

Frame Materials That Handle Mountain Climate

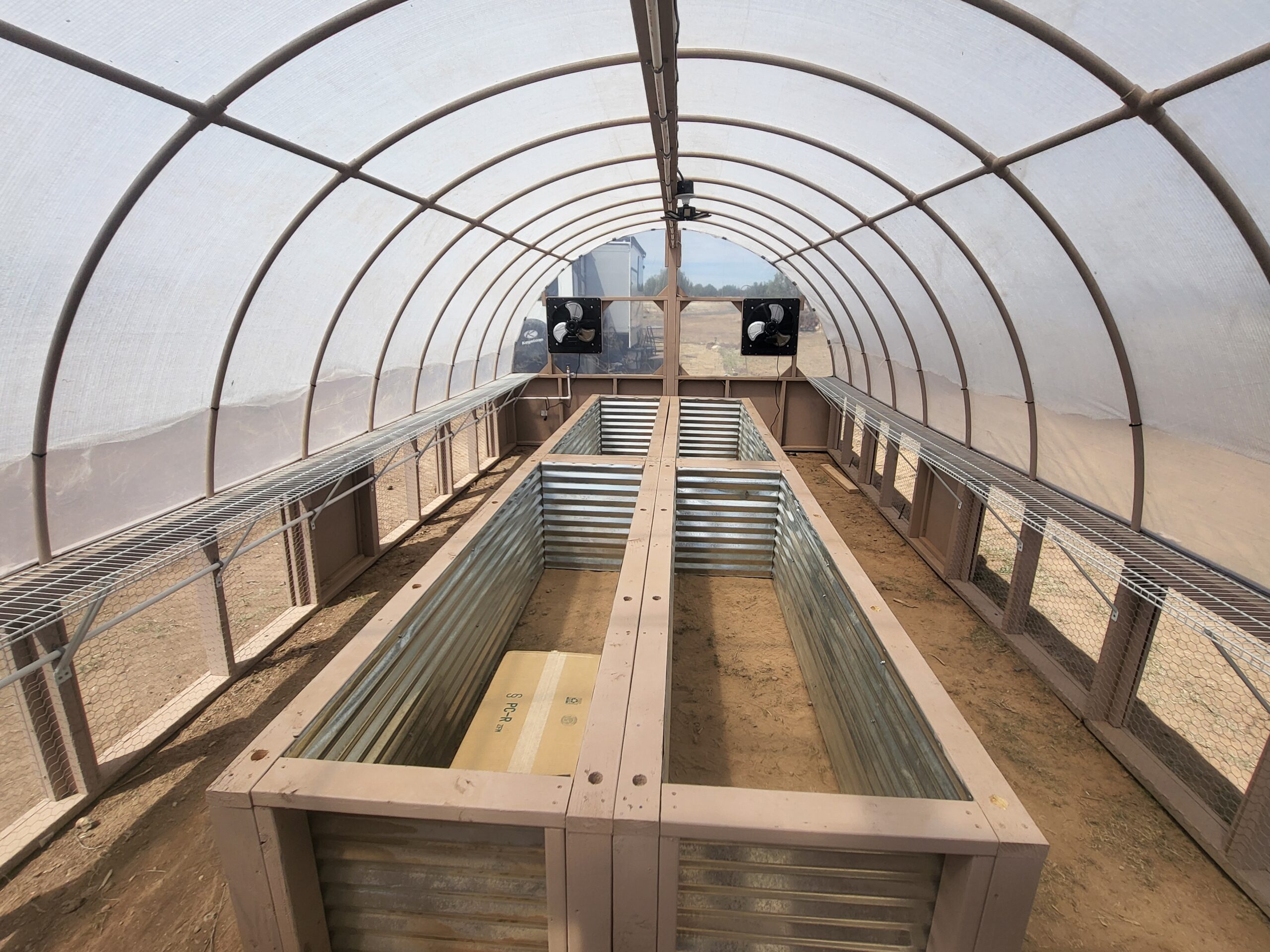

The frame represents the foundation of any hoop house, and choosing the right material matters significantly in Prescott’s environment. Galvanized steel offers the best combination of strength and durability for this region. It stands up to temperature fluctuations without warping, handles wind loads effectively, and resists corrosion from occasional winter snow and summer monsoon rains that arrive in July and August.

Some gardeners consider PVC pipe frames for their lower cost. While these work for temporary seasonal protection, they rarely survive more than a few years in Prescott. The intense summer sun degrades PVC over time, making it brittle, and winter snow loads can crack weakened pipes.

Covering Materials for High Elevation Growing

While investing in pre built hoop houses for home garden in Prescott. keep in mind that greenhouse covering material directly affects the growing environment inside your hoop house. In Prescott, covering needs to balance light transmission, heat retention, and weather resistance. Quality hoop houses use polyethylene film specifically designed for agricultural applications.

Agricultural greenhouse film incorporates UV inhibitors that prevent sun damage, extending the covering’s lifespan to around four years before replacement becomes necessary. This specialized film typically measures 10 mil in thickness, which offers durability without sacrificing light transmission. Quality greenhouse film allows approximately 84 percent of available sunlight to pass through, providing plants with sufficient energy for photosynthesis while protecting them from direct exposure to harsh elements.

Double-layer polyethylene systems provide additional insulation value for gardeners planning year-round production. Air blown between two layers of film creates an insulating barrier that reduces heat loss during cold nights, maintaining more stable temperatures and protecting plants from the significant temperature swings between Prescott’s daytime warmth and nighttime chill.

End Wall Construction and Ventilation

End walls serve multiple functions beyond simply closing off the structure. Quality construction uses dimensional lumber or steel framing to create stable surfaces for doors, windows, and ventilation openings. Lumber end walls work well when treated with preservatives to resist moisture damage.

Ventilation becomes particularly important during summer months when afternoon temperatures climb and greenhouse interiors can quickly overheat without air circulation. Roll-up sides allow gardeners to adjust ventilation based on current conditions, opening during warm afternoons and closing at night when temperatures drop.

Making Material Choices That Last

Selecting materials for pre built hoop houses for home gardens in Prescott requires balancing immediate costs against long-term performance. Structures built with galvanized steel frames, quality agricultural polyethylene covering, proper ground anchoring, and well-constructed end walls provide decades of reliable service with minimal maintenance.

Cheaper alternatives using lighter materials might seem attractive initially but rarely prove economical over time. Replacing damaged frames, torn coverings, and failed anchoring systems costs more in the long run than investing in quality construction from the start.

When evaluating options, consider asking potential suppliers about material specifications, expected lifespans, and how their structures perform in mountain conditions. Companies with local experience understand which materials work best and can point to existing installations that demonstrate long-term durability.

Call To Schedule A Tour

Call To Schedule A Tour